Module cleaning Systems and Solutions

Automation-Sprinkler based system

Automation-Sprinkler based system

Automation-Sprinkler based system

Sprinkler system is an automation in module cleaning system designed for Bugalows, factories rooftops where the access to panel is not very easy.

Automation- Robotics

Automation-Sprinkler based system

Automation-Sprinkler based system

Robotics is an automation in module cleaning system deployed for large utility level solar plants

Anti Dust Shielding (ADS)

Automation-Sprinkler based system

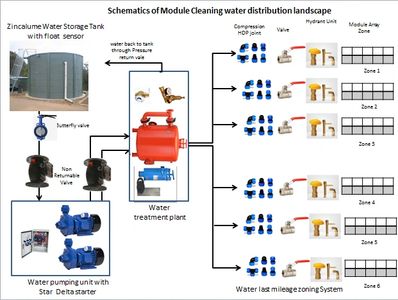

Module Cleaning System-Water Distribution

Anti Dust shielding helps reducing cleaning cycles in the localities where the chemical dust is high.

Module Cleaning System-Water Distribution

Module Cleaning System - Water treatment (RO)

Module Cleaning System-Water Distribution

This is applicable for the solar plants which are spread across large geography and water distribution is very important for module cleaning.

Module Cleaning System - Water treatment (RO)

Module Cleaning System - Water treatment (RO)

Module Cleaning System - Water treatment (RO)

Solar panels are susceptible to mineral deposits of water used for cleaning the modules. The water used from boring is treated for right quality before splashed over the modules using these reverse osmotic (RO) water treatment plants

Module Cleaning System- Water Storage

Module Cleaning System - Water treatment (RO)

Module Cleaning System - Water treatment (RO)

Specially designed storage tank for storing water to be used for module cleaning services

Automated Module Cleaning System- Sprinklers

Preface

Airborne dust particles, sticky tree and plant sap, lichen, soot and bird droppings are just a few of the things that can contribute to a build-up of dirt on your panels. Accumulation creates shading and therefore will prevent sunlight reaching the cells. This results in poor system performance, loss of efficiency and a loss of financial return for the owner and investor of solar energy. Various reports mention losses of up to 10% to 25% in electricity generation as a result of dirt. Most of the time modules are not cleaned regularly due to

- Unavailability of skilled manpower

- Non accessibility to panel areas

- Risk in Climbing high rooftops

Automated Sprinkler System

Sprinko is water-sprinkler based programmable & automated Module cleaning systems helps module cleaning without getting into any inhibitions, and maximizes production from solar panels. Our system offers state-of-the-art automation, Customised for specific soiling environment. System once installed requires minimal maintenance & highly useful where the available water is with high impurities.

Saliant Features

Systemis highly scalable and adaptable to any number & type of panels placed under mixed layouts, be it small Bungalow, factory rooftop or large utility scale project .

The Central unit packaged with various automated facilities like

- To add cleaning agent for soft cleaning

- Water treatment plant to manifest clean water during cleaning

- Angular sprinklers to offer water throw of 2/4/8 meter covering 90 / 180 / 360 degree ensuring optimal usage of sprinklers and water.

- User friendly micro controller helps programing cleaning schedule for a day.

Automated Operations

It is suggested to operate Sprinko system during night or early morning, when solar panels are relatively cold & moist , for 15 to 25 minutes. Customer are facilitated to set convenient cleaning schedule through micro-controller and allow module cleaning done unattended.

Benefits

•Sprinkler water umbrella ( 1.6m) uses gravitation force and inner pressure ( 2 BAR) to clean the modules

Fully automated cleaning

Since there is no rubbing, Module PV area is protected from scratches and undue pressure on PV area

Automatic rain sensor for cancelling cleaning cycle during actual raining

Uses 1.75 Ltr of water per module cleaning

Least water wastage on ground

No risk and threat to human life when modules are installed on height

All Sprinkler system accessory components being special plastic , no regular maintenance is required

Can be connected to existing water harvesting system

Module Cleaning can be done on every day basis , hence the generation results are better

Improved Electricity Generation by 5% to 10%

Sprinko Video links

https://drive.google.com/file/d/1PRlbbFm6TnvsuvaaYNnx_WpZtTHtqrTJ/view?usp=sharing

Robotics Module Cleaning System

Our Technology Partner for "Zero" Robot

Module cleaning Robots are indigenously designed and manufactured by M/s Jetsons Robotics Pvt Ltd, in India

Authorized Master Distributor for Jetson Robotics

M/s Plasmaberry Solar is a sole distributor of M/s Jetsons Robotics for their module cleaning robots in India.

Technical Specifications of "Zero" Robots

- Supports Water & Water less Cleaning.

- Portable from Table to Table.

- Row Heights supported 2 M , 4 M.

- Row Length Supported 1200 M.

- Re-Chargeable Battery / Solar Powered.

- Cleaning Speed – 8-10 meter/minutes.

- Remote / Local programmable

- Warranty – 1 Year or 3 Year(express).

- Brushes - 6-6 Soft Nylon bristles.

- Travels over aluminum frame of module.

- Compatible with most of modules.

- No rails required till module gap is more than 150 mm.

- Continuous usage of 4 Hrs per day .

- Dimensions (HxWxB) – (2/4)x 0.14 x 0.5 M.

- Weight – 25 Kg.

Performance Statistics

- Min. Cleaning wattage/day - 1.04 MW/Day/robot

- Optimum Cleaning Target/day - 3456 Panels/day/ Robot

- Robot Cost/Gross Merchandise MWp**- 350/- *at peak utilisation

- Module Cleaning Cost / Panel ( Gross Merchandise) - 0.20/- to 0.30/- /panel at peak utilisation

*Peak Utilisation of the cleaning frequency is selected such a way that Robot is used for min 4 Hrs per day for min 26 days of a month.**Gross Merchandise MW is total amount of MW that needs to be cleaned in 3 years taking into consideration frequency of cleaning. Modules are assumed to be of 300 Watts# The cost of Robot mentioned above is indicative and has variances based on size of the plant, cleaning frequency and % utilization. It also does not take care of other cost associated with module cleaning like operating manpower, water, electricity etc.

Benefits of Jetsons Module Cleaning Robot

•High Quality & uniform cleaning quality

•Offers higher no. of cleaning cycles per month hence higher power generations

•Operates on chargeable batteries, which can be charged using solar energy during day

•Conservative usage of water using combination of water-based and waterless cleaning cycles

•Ease of portability, mobility, serviceability and maintainability.

Video Link - https://www.dropbox.com/s/flh491ijzx24ym9/Actual%20Sit.mp4?dl=0

Center of Excellence Partner Program

To create customer experience, Plasmaberry has launched Center of Excellence Partner program. For more details , look out for the section Partner Program or download COEPP document.

Modular Robots

Robotic Module Cleaning System

Jetsons Robotic module cleaning system offers variety of models that supports various needs of the customer.

Modular Robots for Module Cleaning

Jetsons Robotics has devised new family of Robots which are modular to adjust various Row heights depending on customer site requirements. Current model supports 2M, 4M, 6M without losing any of it's flavor of portability.

How does modular Robot works ?

Standard robotics system of 2M row height is fixed on movable chassis. The chassis height can be selected based on the Row height requirements of the specific solar project. Entire chassis moves on the Module table and cleans 2-M height in one pass.

- Modular Robot offers complete flexibility on the table row height, right from 2-M, 4-M, 6-M.

- 2-M cleaning robot is fixed along with Chassis to support 4-M or 6-M length.

- Robot cleans 2-M height row in one pass.

- Robot makes 2 or 3 passes for cleaning 4-M and 6-M row height respectively.

- Cleaning speed reduces to 1/2 , 1/3 as row height increases to 4-M & 6-M respectively,

- Cleaning Robot is manually adjusted for upper or bottom row before cleaning cycle is started.

- The chassis can be moved from one table easily.

Benefits of Modular Design

- Since the Robots used in this system is of standard 2M length, customer can use Robotic system for cleaning 2M, 4M, 6M row heights by choosing appropriate chassis.

- Even the Solar projects having combination of Row heights can be supported using multiple chassis.

- Chassis being light weight, the entire unit is portable from one table to another irrespective of the Row height.

Anti-Dust Shield ( ADS) treatment

Additional Information

- Anti Dust Sheild (ADS) treated panels resist build up of dust, dirt due to Bird Dropping, Sand Abrasion, Carbon particles etc

- Easy to clean / self-cleaning effect as water rolls of the surface

- UV-stable, resistant to abrasion, stable at varying temperatures

- Simple application; cures at atmospheric temperature

- Biologically safe and Ecologically beneficial

- Effective in salty environments

- Reduced panel cleaning cycles

- Improved power output

- 1 / 2 Years guarantee

Module Cleaning System

Water Distribution System

Water Distribution System

Water Distribution System

Water distribution system involves pumping unit, HDPE pipeline and quick release valves.

- Pumping Unit - The unit comprises of precise design of water pumps ( monoblock or vertical inline ) to offer end point pressure of 4 BAR. The unit is protected with motor over running due to lack of water and over current. The control panel ensure smooth start of pump.

- The pipeline is designed such a way that water reaches to all the modules with least resistance. Either PVC or HDPE pipes are used for the distribution. HDPE pipes are joined with compression fittings for longer durability.

- At strategic point brass quick release valves are used along with swivel based and service saddle to connect hose easily.

Water Treatment System

Water Distribution System

Water Distribution System

Reverse Osmotic water treatment system is custom-made packaged unit to treat all types of water problems. It can be easily installed for diverse residential, commercial and industrial application. The system is designed for TDS ( total dissolved solids ) of 1500 ppm. However, the system can be redesigned as per the water analysis provided by the client.

The standard sizes available are 500 / 1000 / 1500 / 2000 Ltr/hr.

Zincalume based Water Storage System

Zincalume based Water Storage System

Zincalume based Water Storage System

We use storage tanks made out of Zincalume sheets for the water storage, for module cleaning services.

Zincalume steel has an alloy coating with 150 / 1100 gram/m2 coating equally on both sides of the coated strip. These sheets worldwide have set the standard for corrosion resistance and long life and are manufactured as per Australian Standard AS 1397:2002, American Standard ASTM A792M and Indian Standards IS 15961:2012 & ISO 9364. Zincalume steel has the following major advantages over Zinc Galvanized sheets in the same environmental conditions: Zincalume steel delivers outstanding durability, with a lifetime up to four times that of ordinary galvanized steel against corrosion.

The sizes of the tank are custom built

Module Cleaning System Schematic

Zincalume based Water Storage System

Zincalume based Water Storage System